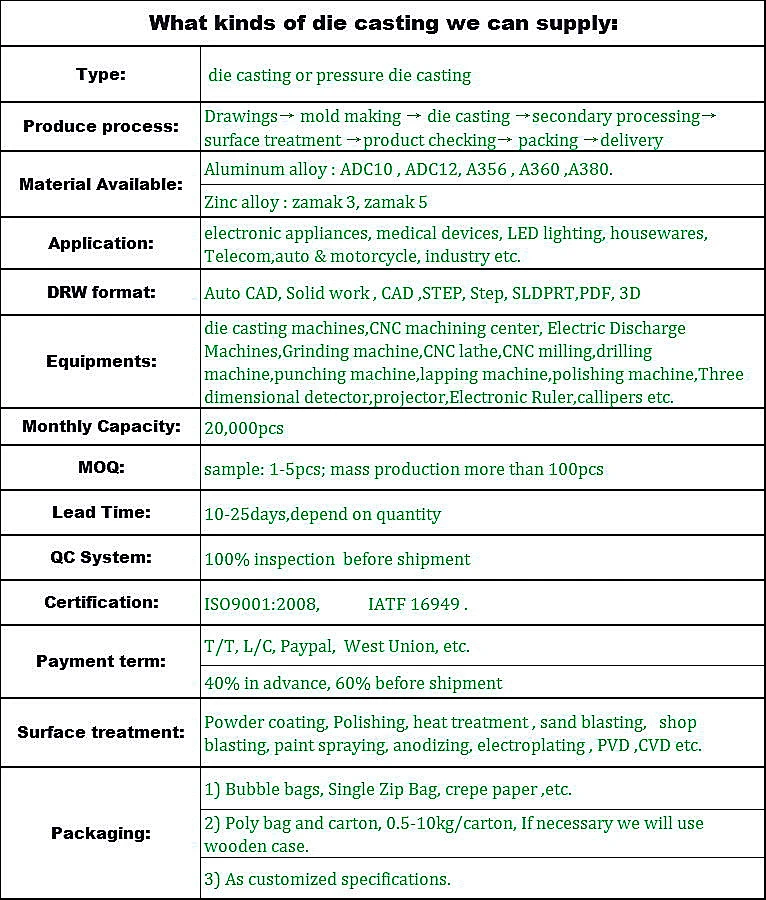

| Material | ADC-12,A380,Alu.6061,6063,zinc 3# etc. |

| Specification | As pern your PDF,CAD,Solide work,Proe drawing or samples |

| Casting Process | Gravity casting, Sand casting, Die casting, |

| Casting Material | Aluminum, Aluminum alloy, zinc alloy |

| Casting Weight | 30G |

| Casting Standard | ISO, ASTM, EN, DIN, JIS, BS, etc. |

| Casting Tolerance | As drawing or samples |

| Surface Roughness | Ra 1.6um-12.5um |

| Surface Operation | Polishing, Sand Blasting, Plating, Paint, Powder Coating, Anodizing,chrome plated etc. |

| Heat Treatment | Quenching, Annealing, Aging, etc. |

| Equipments | die casting machines,CNC machining center, Electric Discharge Machines,Electric Discharge Machines,Grinding machine,Computer gong machine,CNC lathe,CNC lathe,drilling machine,punching machine,lapping machine,polishing machine,Three dimensional detector,projector,Electronic Ruler,callipers etc. |

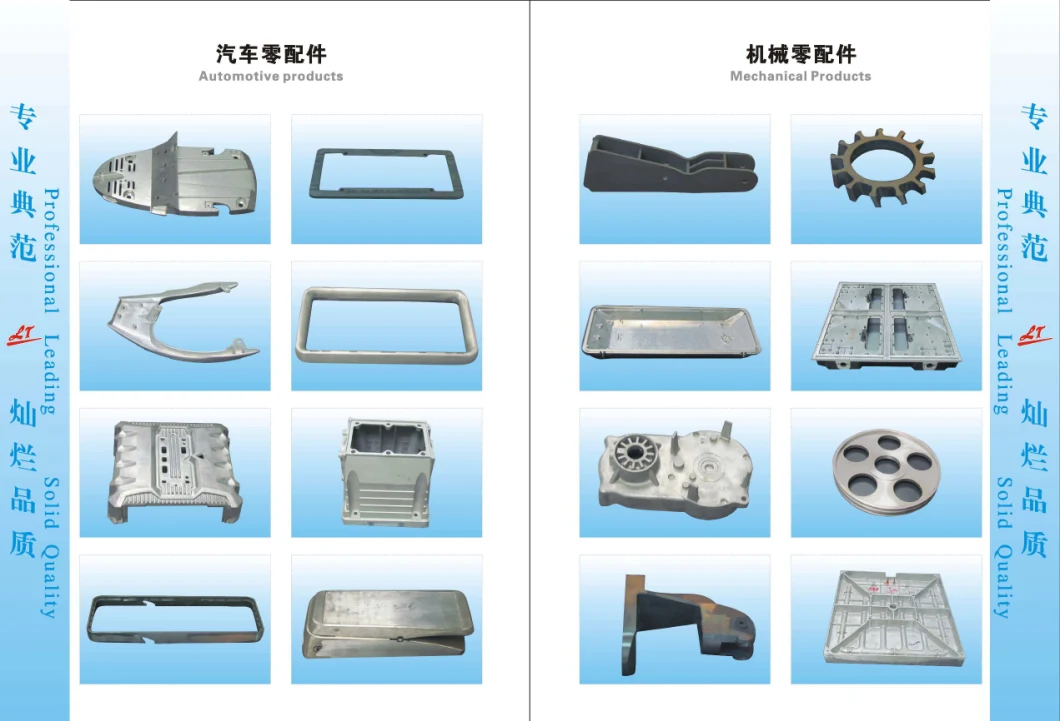

| Usage | electrical appliances, medical devices, LED lighting, housewares, Telecom, communication,auto & motorcycle,military equipment product industry etc. |

| IPQC | IPQC through the whole machining process, spot inspection for material coming-in, spot inspection for machining process and final inspection based on AQL |

Company Profile

Lituo Metal Die Casting Co., Ltd., a factory cover 20, 000 square meters, has more than 12 years' experience in developing and providing highest quality die casting parts and mould, CNC machine parts for China and oversea clients! Our products are very popular in Europe, America, Japan and South Korea.

We are a professional and experienced manufacturer of following parts in different design and sizes for all types of industries such as electrical appliances, medical devices, LED lighting, housewares, Telecom, communication,auto & motorcycle,military equipment product industry etc.

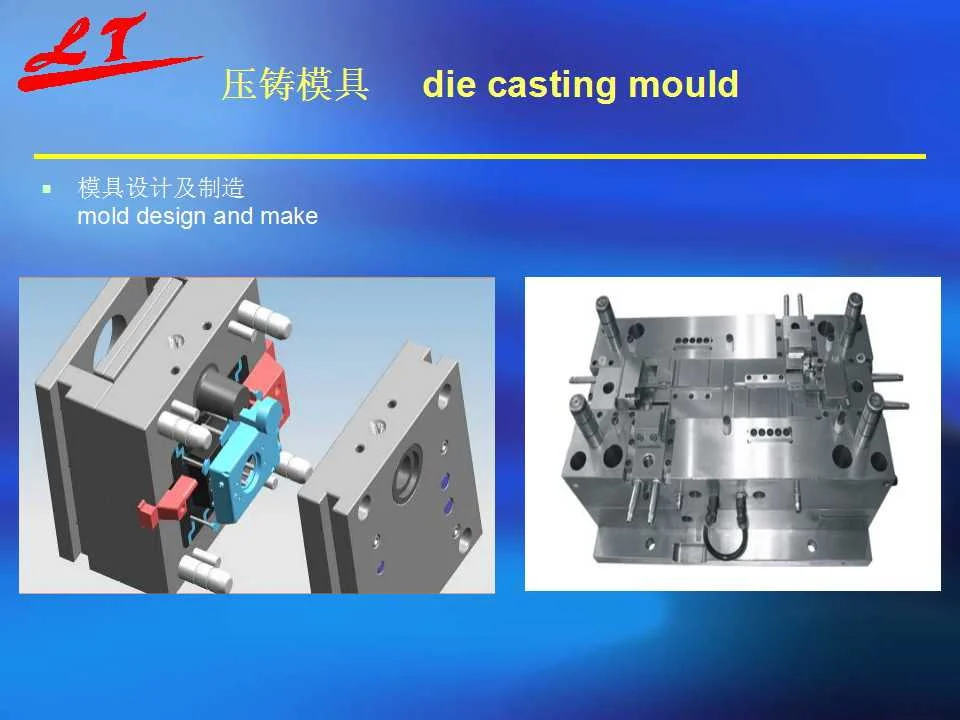

We have advanced Equipment and instruments, such as 4 sets of cold chamber Zinc alloy die casting machines, 6 sets of hot chamber Aluminum alloy die casting machines, 15 sets of CNC lathe machines etc.

Certificates:ISO9001:2008,SGS,ROHS

Our Advantage

1.GOOD QUALITY-have the significant advantages in the performance of strength, durability.

2.RICH VARIETY & WIDE USES.Such as electrical appliances, medical devices, LED lighting, housewares, Telecom, communication,auto & motorcycle,military equipment product industry etc.

3.Reasonable Price. Exquisite workmanship with competitive price.

4.EXCELLENT SERVICE-Strong R&D team,Professional Foreign Trade service team,Convenient transportation advantage on Sea/Land/Air shipping.

5.Eco-friendly,safe,easy to use.

Our Goal

Custom and Standard Manufacturing Service

A variety of Manufacturing Process Integration

Quality and Delivery Time Guaranteed

Effective Communication Ability