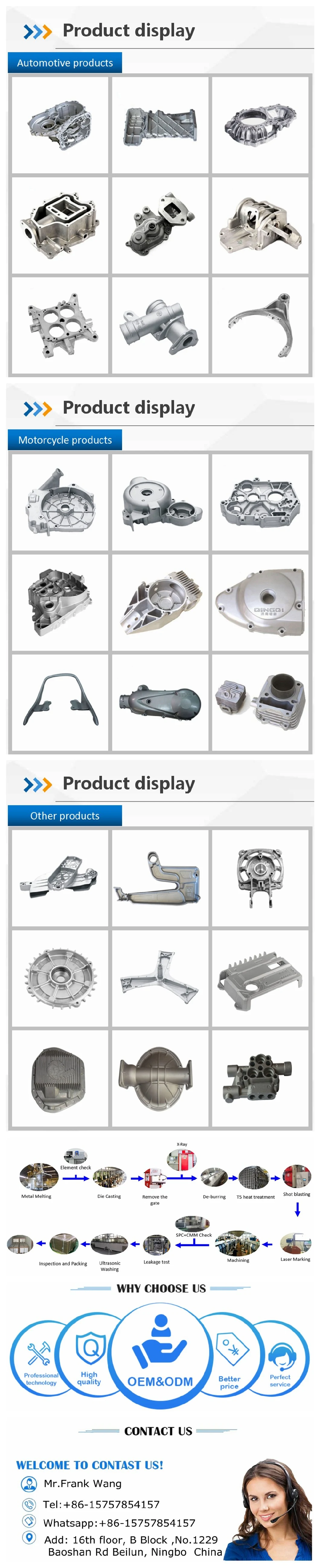

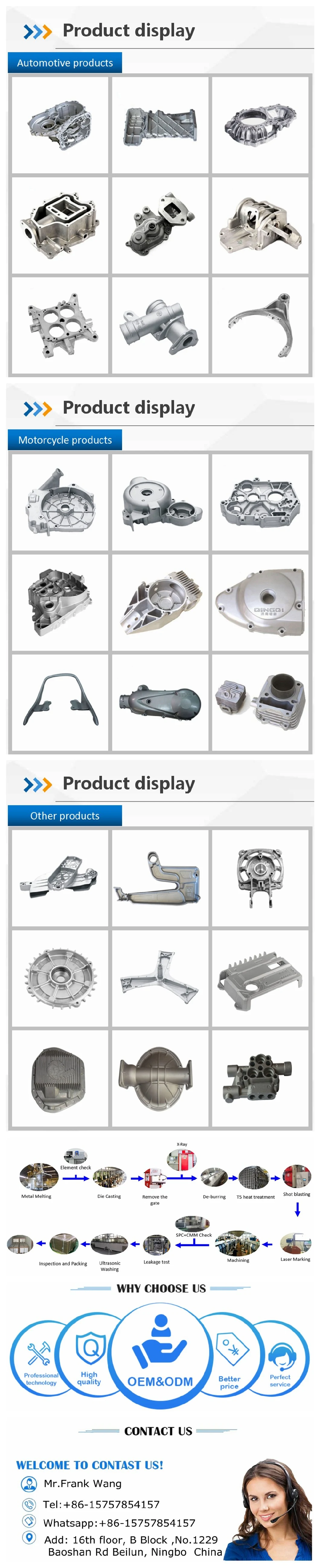

We are a die casting product supplier. We have 20 manufacturing experience. Our main products include auto parts, motorcycle parts, power tool parts, communication tool parts, lamp parts, medical equipment parts, escalator parts, etc.

Service:

1) Experience in casting for many years and served customers all around the world.

2) International advanced-level equipment such as CNC, numerical lathes. CMM.

3) OEM service, you demand is our pursued.

4) ISO quality control

FAQ:

1. How can I get the quotation?

Please send us information for quote: drawing, material, weight, quantity and request.

2. If we don't have drawing, can you make drawing for me?

Yes. we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 35-40 days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time: 35-40 days after the payment. The accurate time depends on your product.

5. What is your payment method?

Tooling: 100% TT advanced.Main order. 50% deposit, balance 50% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP,X_T,MAX..

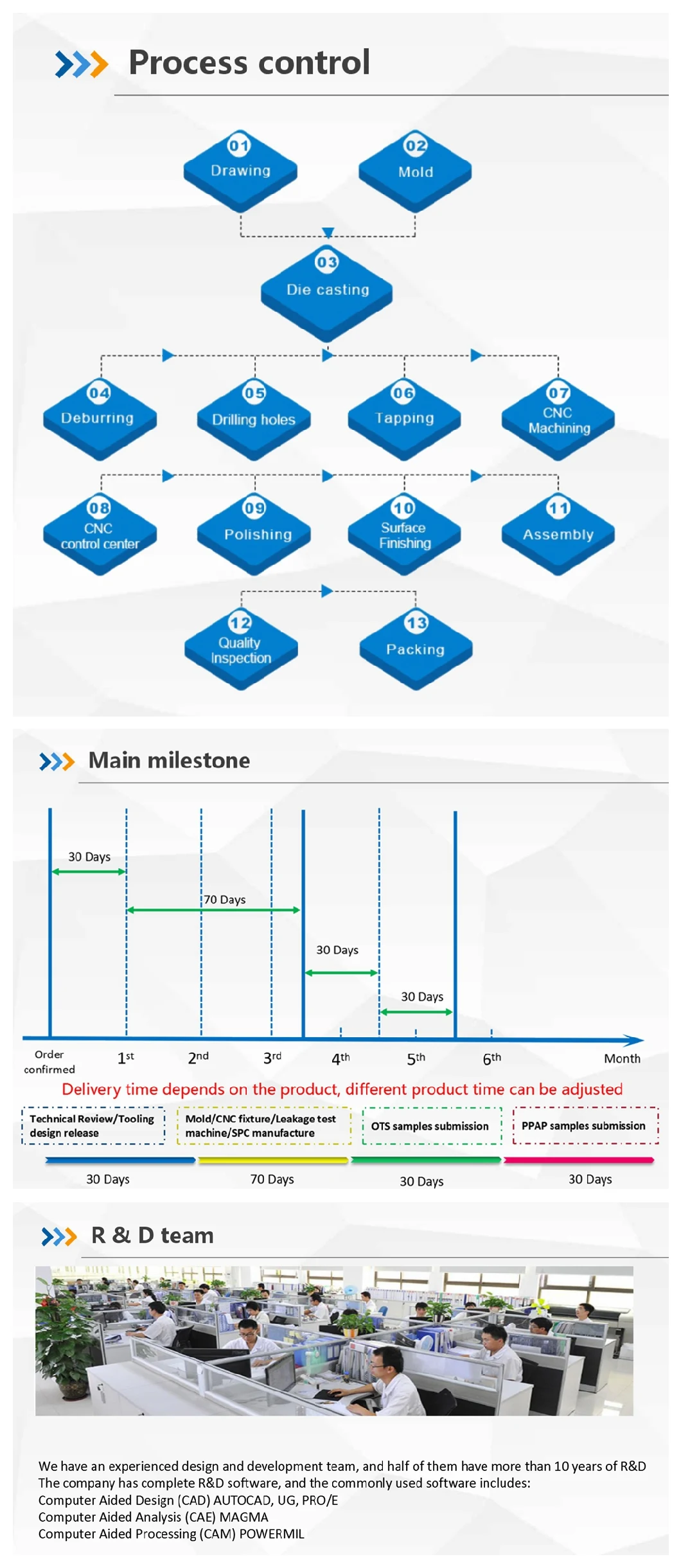

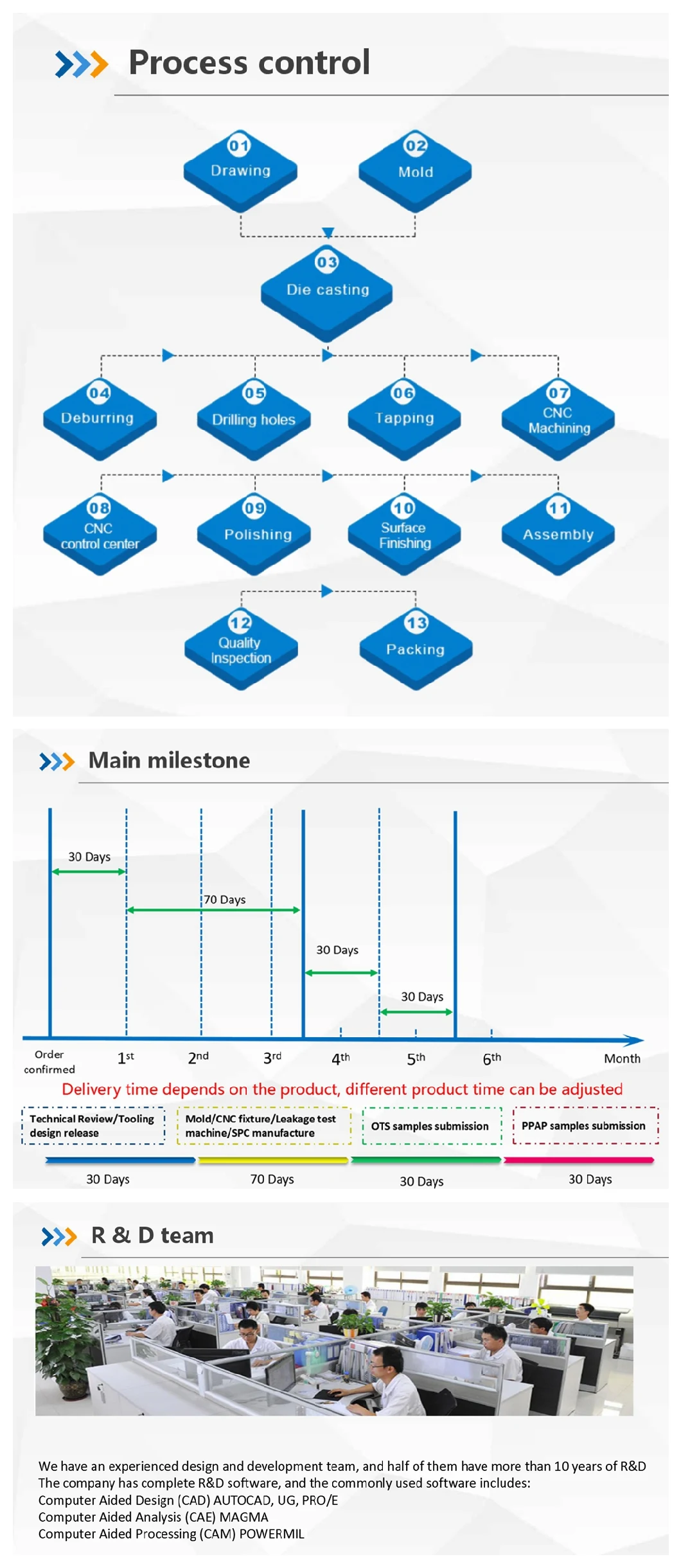

| project | description | |

| Die Casting | Die casting product forming technology | Die casting mold |

| Die casting product material | Aluminum alloy:ADC12,A380,AlSi12Fe, AlSi9Cu3,A356, ADC14, A380, A390And other aluminum alloys Zinc alloy:Zamark 3, Zamark 5, Zamark7, Zamark8 magnesium alloy: AZ91D | |

| Die casting product size | NADCA based accuracy level | |

| Die casting product surface treatment | Sand blasting, spray painting, powder coating, anodizing Galvanized, chrome plated, nickel plated, etc. Coating, powder coating, anodizing, black oxide Coating, nickel plating, etc. | |

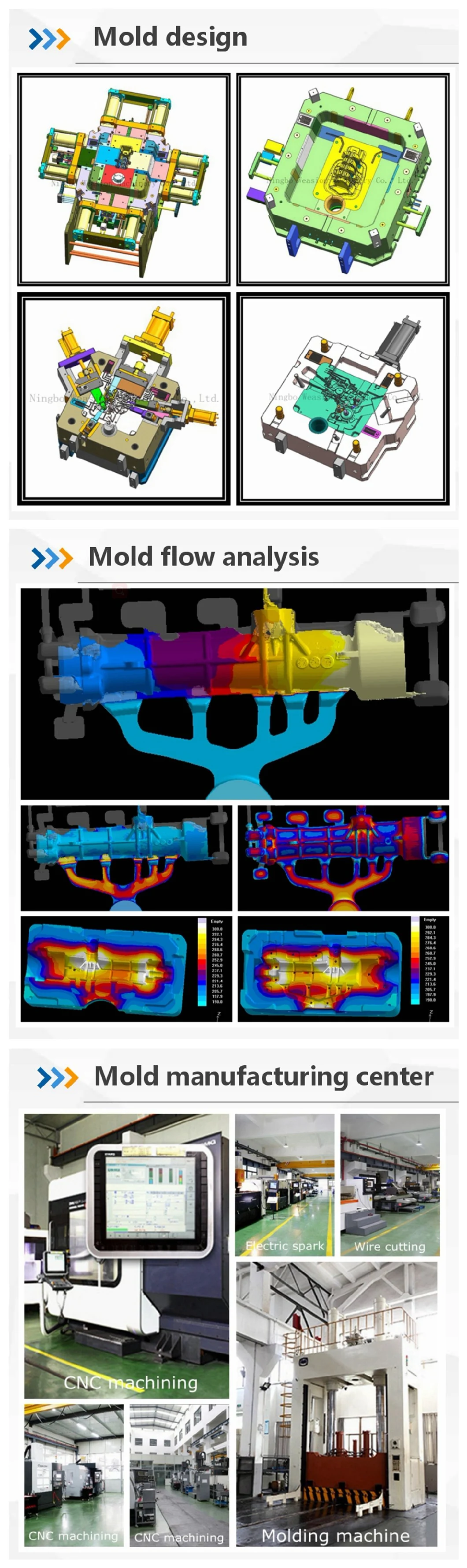

| Die casting mold | Mold cavity | Single or multiple |

| Mold material | H13,1.2344,8407,DIEVAR,TQ1,SKD61,45#Steel, etc. | |

| Heat treatment | Hardening, nitriding | |

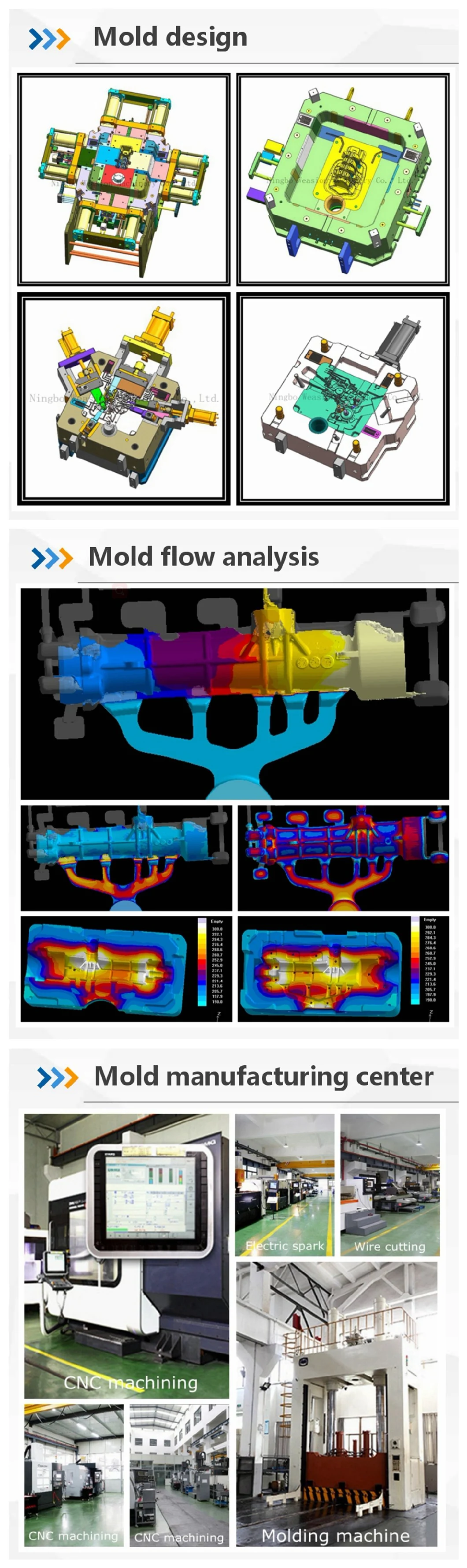

| Die casting mold features | Advanced design, novel structure, high precision, high quality materials, long service life and short delivery time | |

| Mold manufacturing equipment Check tool | CNC precision machining, die-casting mold engraving machine, CNC forming machine, CNC turning, EDM, wire cutting machine, , die casting machine (180T~2500T), lathe, grinding machine, material detector, hardness testing equipment, spectrograph, etc. | |

| Die casting mold design software | CAD,UG,Pro / E,MAGMA, etc. | |

Service:

1) Experience in casting for many years and served customers all around the world.

2) International advanced-level equipment such as CNC, numerical lathes. CMM.

3) OEM service, you demand is our pursued.

4) ISO quality control

FAQ:

1. How can I get the quotation?

Please send us information for quote: drawing, material, weight, quantity and request.

2. If we don't have drawing, can you make drawing for me?

Yes. we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 35-40 days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time: 35-40 days after the payment. The accurate time depends on your product.

5. What is your payment method?

Tooling: 100% TT advanced.Main order. 50% deposit, balance 50% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP,X_T,MAX..