Mould Features and Equipment Lists

2) Cav/core material:H13, 8407 etc

3) Single or multi cavity die casting moulds

4) Hardness of steel:40-60 HRC

5) Lead time:2-4 weeks depending on products

6) Product Material:Aluminum alloy, Zinc alloy

7) Suitable for both cold chamber and hot chamber machines

8) Machine Size:

Aluminum Die Casting Machine:125T-800T

| EQUIPMENT LIST | CAPACITY | QTY |

| COLD CHAMBER DIE CASTING MACHINE | 125 TONS | 2 SETS |

| COLD CHAMBER DIE CASTING MACHINE | 250 TONS | 2 SETS |

| COLD CHAMBER DIE CASTING MACHINE | 350 TONS | 1 SET |

| COLD CHAMBER DIE CASTING MACHINE | 650 TONS | 1 SET |

| COLD CHAMBER DIE CASTING MACHINE | 800 TONS | 1 SET |

| GRAVITY MACHINE | 750mm*630mm | 3 SETS |

| CNC LATHE MACHINE | 10 SETS | |

| MILLING MACHINE | 8 SETS | |

| DRILLING MACHINE | 20 SETS | |

| TAPPING MACHINE | 10 SETS | |

| VIBRATE POLISH MACHINE | 3 SETS | |

| SAND BLASTING MACHINE | 1 SET | |

| POLISHING MACHINE | 30 SETS | |

| CHROME PLATING LINE | NICKLE,CHROME(MATT/BRIGHT) | 3 LINES |

Surface Finish

1.Satin Chrome 2.Vibratory Finishing

3.Bright Chrome 4.Thermal De-Burr

5.Pearl Nickel 6.Powder Coating

7.Sand Blasting 8.E-Coat

9.Satin Bronze 10.Chromate

11.Satin Nickel 12.Decorative Electroplating

13.Satin Blackened Brass 14.Lifetime Finishes - PVD

Product Description

| Product Name | Investment Casting//Machining Parts/ Custom Aluminum Die Casting |

| Material | ADC10,ADC12, A380, 383, B390 (Yl117), Yl112, Yl104 |

| Making process | Die casting, CNC Machining |

| Surface treatment | Polish, chrome/nickel plating, power coating,PVD, E-coating |

| Application | These parts are used in automotive, electrical, building, furniture, machine assembly, computer components, air industry |

| Company advance | 1. Professional die casting manufacturer and rich experience in die casting parts 2. ISO9001: 2015 Certificated 3. In-house tooling design and manufacturing 4. OEM/ODM orders are welcome, for any stamping parts 5. Advanced equipment, excellent R& D teams and strict quality control system 6. Software for specification drawings: Pro/E, Auto CAD, solid work 2001, CAXA, UG, CAD, CAM |

Our die casting parts are widely used for Auto industry, Locking systems, Bathroom Accessories, Window and Door systems, Furniture, Medical industry, Electronics, communications system etc.

In our showcase, you can see all kinds of customized products which are developed by our professional engineers, according to customers' different requirements. We sincerely welcome customers all over the world come to visit at any time.

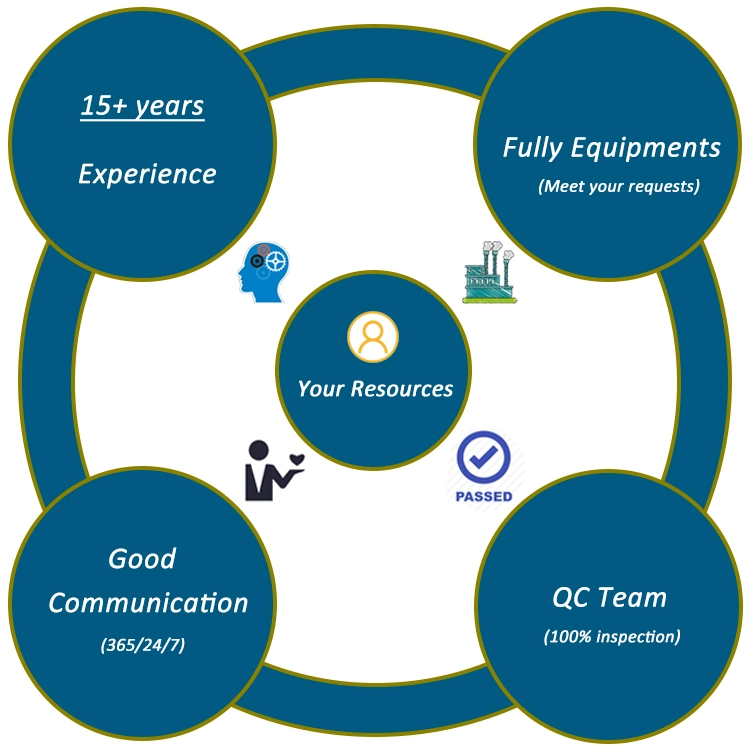

Company Introduction

Xiamen Stick Industry Co., Ltd was established in 2004, located in Xiamen, South of China. It has more than 14 years experience of manufacturing and exporting all kinds of Aluminum die castings, Zinc die castings, Gravity die castings and CNC Machining parts etc.

Covering an area of 8,000 square meters, our factory consists of 8 overseas sales representatives, 10 professional technicians and 160 workers standby. We have passed the certificate of ISO9001:2015 and international quality system TS16949.

Currently our workshop equipped with 7 sets of hot chamber die casting machines. Ranged from 125 tons to 800 tons, which can die cast aluminum items from 5g to 35kgs as per customers' requirements. Our CNC milling machines and CNC lathe machines can meet tight tolerance requirement for zamak parts. Our secondary machining capacity including CNC turning, milling, machining, grinding, drilling, tapping, assembly to final package.

We have a comprehensive production line, and equipped with advanced facilities. The Factory is consist of the below departments, as Casting Dept, CNC Machining Dept, Polishing Dept and Plating Dept etc. At the same time, our quality inspector will daily check the production staus, include the 5S sanitary environment and guarantee the good quality, and get rid of the defects.

The nice circumstance will creat better working effeiciency. The unit weight around 10g to 5kg. Maximum Size: 600mm

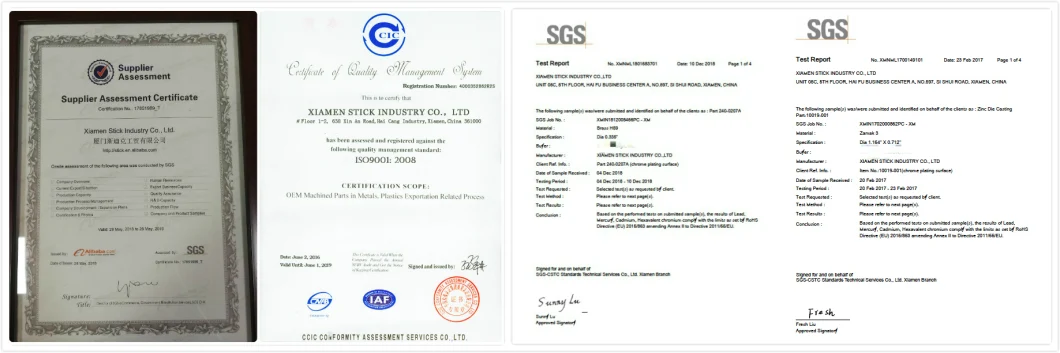

The Certificates

Stick Industry knows its mission, which provide better service to our clients, and guarantee products quality.

We have acquired series of certificates like ROHS, SGS, ISO9001:2015, TUV and UL.

Our quality department is equipped with advanced inspection equipments. Such as salt spray test, tensile testing instrument and hardness tester etc.

Quality principle:Strength quality awareness, implement full participation, facilitate continuous improvement, and keep customer satisfied.

We insist that no production of defects, no outflow of defects, no acceptance of defects.

Packing&Shipping

Packaging Details: PP bag , carton box , pallet or as customer request for products. Delivery Detail: The products are usually shipped in 30-40 days after payment.

FAQ

1. Are we a manufacturer or foreign trade company?

We are an experienced manufacturer, and have our own facotry and warehouse.

2. What do we need if you want a quote?

Please kindly send us your 2D and 3D drawing of your product. the details we need as below:

1.Materials 2.Surface Finish 3.Estimated Quantity

It is very important for us to provide a quote.

3. How does the payment process work?

Our preferential payment term is T/T

For mould: 50% downpayment, 50% balance after the sample approval

For Production: 50% downpayment, 50% against B/L copy

4. How do I know about the production?

We will double confirm your requirements and send you the sample before the mass production. During the mass production, we will keep you informed of any progress. Besides, we will do 100% quality inspection before shipment.

5. How do we know about the delivery status?

We will immediately inform you the tracking number once we get it from shipping agent. Besides, we will update the latest shipping information to you.

6. What is our Mission?

Our mission is to enlarge our sales network and reach to all customers by manufacturing the high-end products with guaranteed quality and unparalleled price, maintaining same levels of quality and professionalism while providing the customers the latest products at any time.

Stick Industry devotes to provide best solutions to clients, because of their innovations, outstanding design and unexceptionable products.By a combination of their advanced craftsmanship and their cutting-edge approach to effective teamwork and processes, our Technology take the lead in developing, designing and manufacturing our outstanding product range, all the while testing and fine-tuning each piece to ensure continued customer satisfaction.

We always commit to provide best products and service, and convenience to customers.