Our company can supply various Sand Casting Parts (OEM) according to the customers' drawings and requirements. Please offer us your enquiry with detailed drawings, specifications, unit weight, quality requirements and pictures. We will supply you not only the products with good quality but also competitive price and satisfactory service!

- Material: Ductile iron, Stainless steel , Steel, Grey iron, Aluminium alloy, Copper alloy.

- Process: Sand Casting.

- Heat Treatment: Quenching, Tempering, Annealing, Normalizing, Nitridation, Carburization.

- Surface Treatment: Zinc-Plated, Hot dipping galvanized, Polishing, Painting, Powder coating.

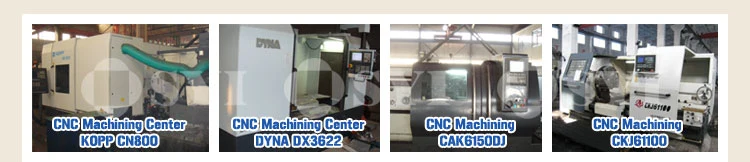

- Machining Equipment: CNC Machines, Turning Machines,Drilling Machines , Milling Machines, Grinding Machines,etc.

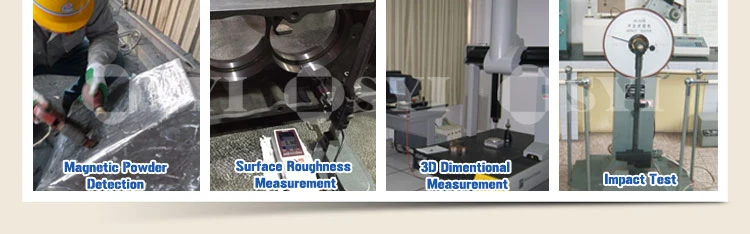

- Measuring Tool: CMM, Projector, Vernier Caliper, Depth Caliper, Micrometer, Pin Gauge, Thread Gauge, Height Gauge, etc.

- Weight: 0.1-3000kgs.

- Application: Machinery Parts, Construction Industry, etc.

- Package: Plywood or wooden case, pallet (As per customer's requirement).

With our powerful precision CNC machining equipments such as lathes, milling machines and drilling press, we can easily operate Turning, Drilling and Milling. Furthermore, we are able to run other operations like cutting, grinding, bending, shaping, planning and sawing.

Overall product quality inspections is from raw materials incoming inspection, semi-finished products inspection, specimen testing, and products testing. We strictly follow the procedures of ISO 9001, IQC, IPQC & FQC. SYI has independent inspectors and QC engineers to check & record in accordance with the procedure and submited for approval/audit.

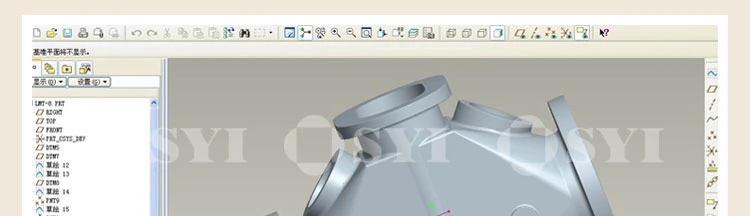

SYI Group has 26 years of independent development and design ability. We have 30 senior engineers, who is skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop, produce and deliver your PO according to your drawings, samples or just an idea. Dual control of standard products and OEM products.

We Are Certified

We Are Certified

SYI Group achieves the certificate of ISO 9001:2008 for the Quality Management System from TUV Rheinland. Meanwhile, SYI Group holds the Kitemark License/BSI/SGS/BV/NF/CE/WRAS/UL/FM certificates for different products.

SYI Industrial Co., Ltd.

Best Regards

SYI Group

You will get our quick reply!

SYI Foundry is also able to manufacture shell mould casting product.

2), Material

Ductile iron, Grey cast iron, Carbon steel, Alloy steel, Special alloy steel and Stainless steel, copper, bronze and brass

3), Designs

* As per the customer's drawings

* As per the customer's samples

4), Inscription Style

* SYI Foundry

* As per customers' requests

* Standard Inscription

5), Packing

* Wood pallet

* Steel pallet

* As per customers' requirements

6), Inspection

* Foundry in-house

* Third Party inspection available upon requirement

More information is available upon enquiry request.

You will get our quick reply!

| General Capabilities | Design Modeling (2-D, 3-D) | Die Location Technical Support | Inspection |

| Detail Tooling Documentation | DFMEA/PFMEA | Quick Building Prototypes | |

| Die Types | Forming Dies | Precision Progressive Stamping Dies | Secondary Dies |

| High Speed Steel Dies | Precision Blanking Dies | ||

| Tooling Material | Carbide(CD650,V3,KD20) | ASP-23 | ASP-60 |

| S55C---45#55 | AL7075 | SKD11 | |

| Tooling Life | 50 Million to 300 Million Times | ||

| Die Concept | 2-Plate Die | 3-Plate Die | Module Die |

| Production Equipment | CNC | SODICK Nice Surface EDM | P/G |

| Drill | SODICK Wire Cutting Machine | J/G | |

| Milling Machine | WAIDA Profile Grinder Machine | ||

| Stamping Equipment | AIDA | PURDER | KYOL |

| MICO | |||

| Stamping Product | Custom Stamping | SIM Spring | Spring |

| Battery Spring | Shield Drawing | Press-Fit Terminal | |

| Lead Frame | Power Terminal | PC Terminal | |

| Additional Services Provided | Custom Packing | Packaging | Heat Treat |

| Plating | |||