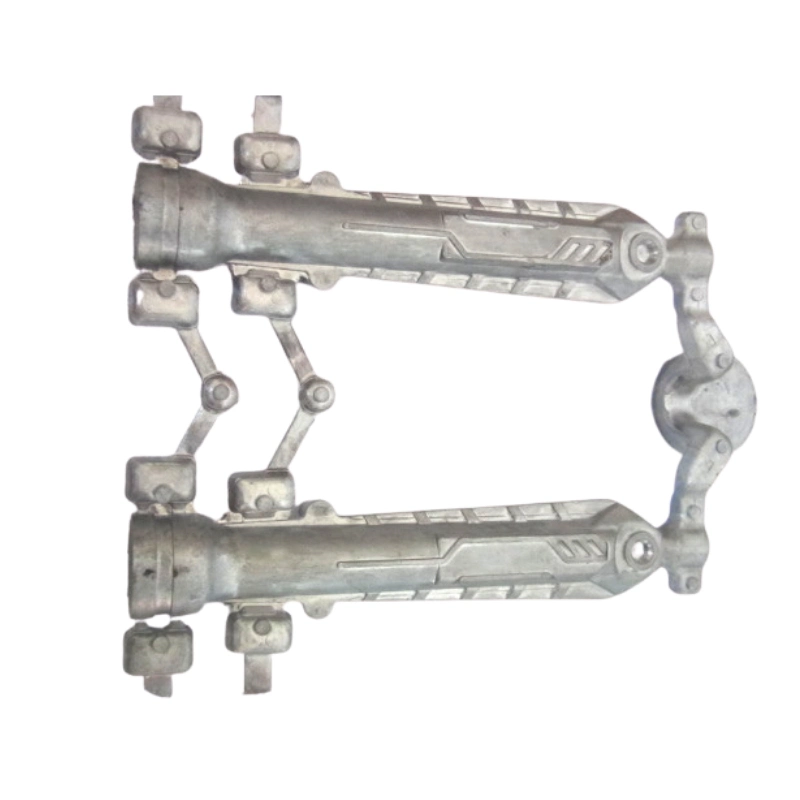

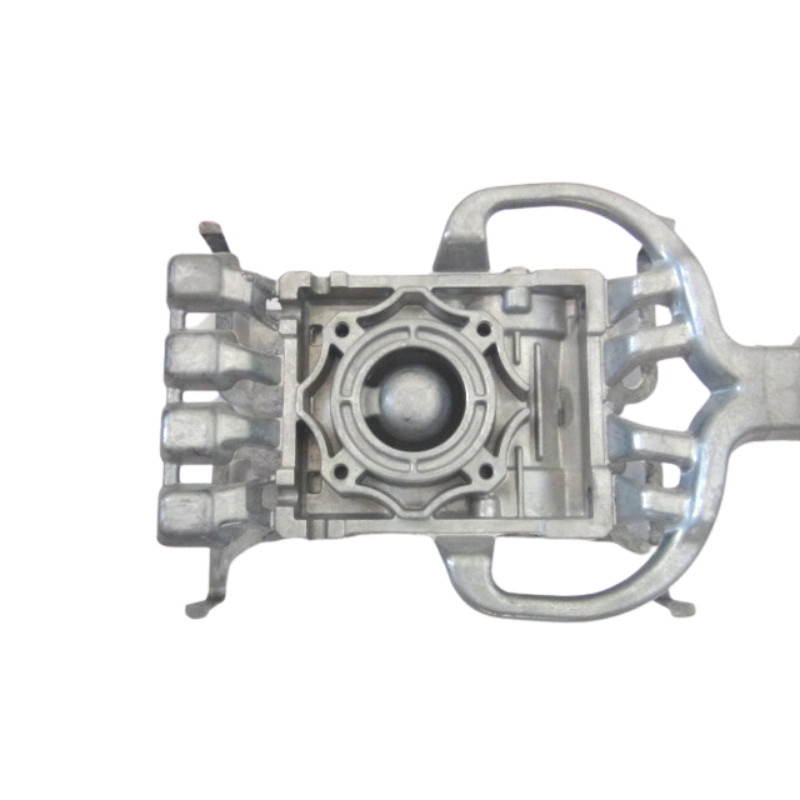

Motorcycle Parts Finish By Die Casting Aluminum Alloy

Product Description| Material | Die casting:A356/A380/A390/A360/ADC10/ADC12/ZL101/ZL102/ZL104/ZL107 CNC machining casting: 6061-T6/6063-T6 |

| Process | Sand casting, Gravity casting, high pressure die casting, low pressure die casting, and CNC Machining casting |

| Software | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Equipment of Casting & machining | Die Casting Machine:10 sets 280T/400T/500T/800T/1250T CNC Machine: 20sets Milling machine/Turning machining/drill and tap machine |

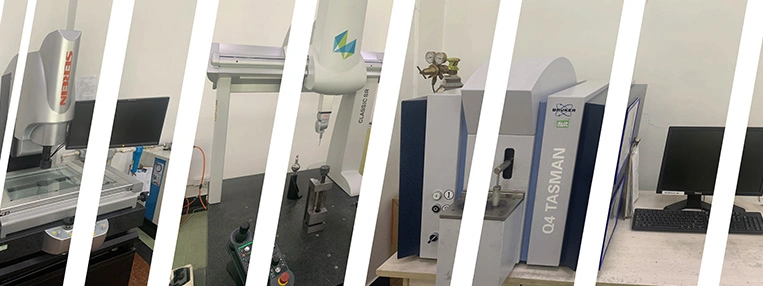

| Inspection equipment | Spectrometer, Tensile test device, Hardness test device, CMM, X-Ray, Leaking test device |

| Precision machining | CNC Turning, Milling, Drilling, Grinding, Cutting, Reaming and Threading |

| Finished | Polishing, Sandblasting, Heat treatment, Painting, Powder coating, Anodizing, Electroplating, Chrome plating, Mirror polishing |

| Application | Vehicle industry Medical device industry Marine industry Lighting industry Oil & Gas Transportation industry Electric Utility & Communication Industries Architectural industry Furniture industry |

Workshop Details

Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ni | Sn | Al |

| ADC12 | 9.6-12.0 | 0.3-0.6 | 3.0-3.5 | 0.3-0.5 | 0.2-0.3 | 0.6-0.9 | 0.2-0.5 | <0.3 | Al |

| A380 | 7.5-9.5 | 1.3 | 3.0-4.0 | 0.5 | 0.1 | 3 | 0.5 | 0.35 | Al |

Inspection Equipment

Our QC team strictly controls quality at each step to ensure the quality of every order.

1.Raw material inspection.

2.Inspection during processing.

3.Finished product inspection.

4.Customer's third party inspection before shipment.

5.Irregular warehouse inspection.

Packagings

1) Polybag and carton

2) wooden Pallet or container

3) As per customized specifications