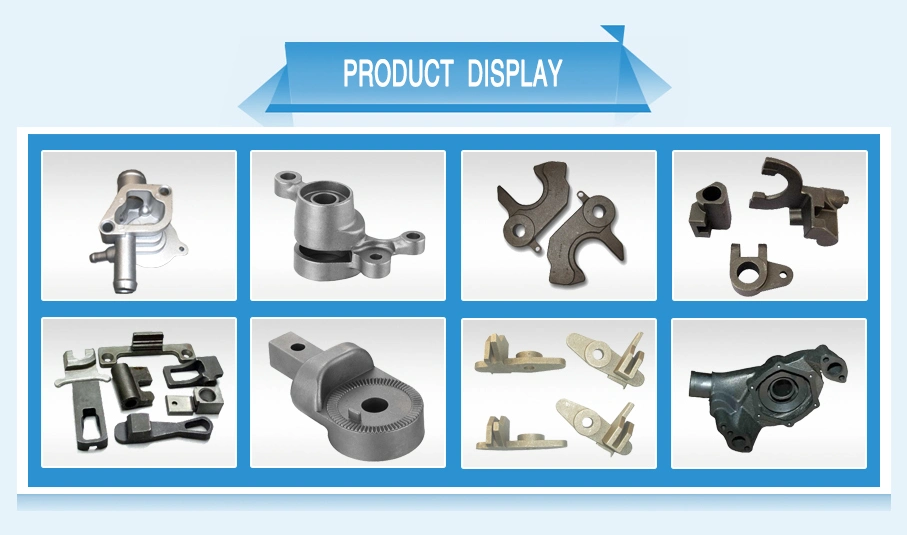

OEM Wrought Iron Foundry Metal Mold Lost Wax Casting Parts

1. ISO9001-2008.

2. Has advanced euipment and over 15 years experience.

3. Price: Competetive price, Precision made. Experience & Reasonable QC that you can reply on.

4. Process: Precision made. Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.

6. Product Name: Investment Casting / Precision Casting Parts / ball Valves / stainless steel sand casting parts / machinery parts / CNC machining parts, Steel Investment Casting / lost wax / casting / die casting

7. Progress of precision casting: Investment casting

8. Precision Casting materials: Stainless steel, Carbon steel, iron steel, alloy

9. We can do different kinds of surface treatment after casting, such as machining, polishing, and plating

10. All sorts of precision lost wax casting product: Marine casting parts, auto parts, machinary casting parts, pump parts, hardware parts

OEM Mental Mold Lost Wax Casting Part with Metal Foundry

Material:

Cast iron (grey iron grade: GG15-GG40, GGG40-GGG70)

Cast steel (Stainless steel, Cast low alloy steel, Special steel casting)

Production capacity :

1.Casting classification:Sand casting;Precision casting;Vacuum process casting etc.

2.Gray iron, ductile iron, stainless steel ,carbon steel,alloy steel, etc.

3.Adoption standard:BS,DIN,ASTM GB etc.

4.Weight range:0.5~5000kg.

5.Producing capacity :2,000 tons per month .

6.Main application:Metallurgy;Machinery;Plastics;Rubber;Pharmaceutical;

Textiles;Mining;Paper-making;Packaging.

7.Main equipments:Furnaces;Heat treatment furnaces;Direct-reading spectrometer;Shot -blasting equipments, etc.

8.Surface treatment:Polishing,plating,shot blasting,heat treatment ,etc

9.Inspection and test:Foundry in home,third part inspection,Material report,UT, MT, RT, and PT,etc..

10.Packing and shipping :Stand export packing;20day make modul & sample;Delivery time against your quantity.

11.Casting service:Your logo, character, trade name, number etc can be casted on the surface clearly.

OEM Mental Mold Lost Wax Casting Part with Metal Foundry

1.ISO9001-2008.

2.Has advanced euipment and over 15 years experience.

3.price: competetive price , Precision made.Experience & Reasonable QC that you can reply on.

4. Process: Precision made.Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.Forging: We can provide forged ring, open-die forging, forged shaft, forged bush, forged shape, drop forging, precision forging, hot-pressed part, upset forging, hot-upset part, forging casting, forged disc, perforated disc.

OEM Customized Metal Iron Casting Parts with Drawings or Samples

OEM Mental Mold Lost Wax Casting Part with Metal Foundry

Q: Why choose Shengao product?

A: We shengao have our own plant-- Weifang Shengao machinery Co.,Ltd, therefore, we can surely promise the quality of every product and provide you comparable price.

Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

Q: Do you provide customized casting products?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there's anything I can help, please feel free to contact with me.

1. ISO9001-2008.

2. Has advanced euipment and over 15 years experience.

3. Price: Competetive price, Precision made. Experience & Reasonable QC that you can reply on.

4. Process: Precision made. Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.

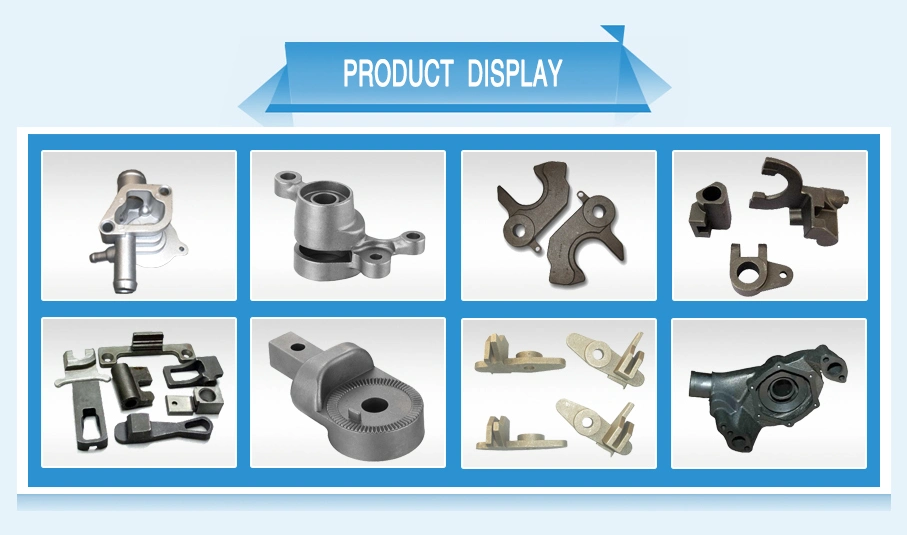

6. Product Name: Investment Casting / Precision Casting Parts / ball Valves / stainless steel sand casting parts / machinery parts / CNC machining parts, Steel Investment Casting / lost wax / casting / die casting

7. Progress of precision casting: Investment casting

8. Precision Casting materials: Stainless steel, Carbon steel, iron steel, alloy

9. We can do different kinds of surface treatment after casting, such as machining, polishing, and plating

10. All sorts of precision lost wax casting product: Marine casting parts, auto parts, machinary casting parts, pump parts, hardware parts

OEM Mental Mold Lost Wax Casting Part with Metal Foundry

Material:

Cast iron (grey iron grade: GG15-GG40, GGG40-GGG70)

Cast steel (Stainless steel, Cast low alloy steel, Special steel casting)

Production capacity :

1.Casting classification:Sand casting;Precision casting;Vacuum process casting etc.

2.Gray iron, ductile iron, stainless steel ,carbon steel,alloy steel, etc.

3.Adoption standard:BS,DIN,ASTM GB etc.

4.Weight range:0.5~5000kg.

5.Producing capacity :2,000 tons per month .

6.Main application:Metallurgy;Machinery;Plastics;Rubber;Pharmaceutical;

Textiles;Mining;Paper-making;Packaging.

7.Main equipments:Furnaces;Heat treatment furnaces;Direct-reading spectrometer;Shot -blasting equipments, etc.

8.Surface treatment:Polishing,plating,shot blasting,heat treatment ,etc

9.Inspection and test:Foundry in home,third part inspection,Material report,UT, MT, RT, and PT,etc..

10.Packing and shipping :Stand export packing;20day make modul & sample;Delivery time against your quantity.

11.Casting service:Your logo, character, trade name, number etc can be casted on the surface clearly.

OEM Mental Mold Lost Wax Casting Part with Metal Foundry

1.ISO9001-2008.

2.Has advanced euipment and over 15 years experience.

3.price: competetive price , Precision made.Experience & Reasonable QC that you can reply on.

4. Process: Precision made.Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.Forging: We can provide forged ring, open-die forging, forged shaft, forged bush, forged shape, drop forging, precision forging, hot-pressed part, upset forging, hot-upset part, forging casting, forged disc, perforated disc.

OEM Customized Metal Iron Casting Parts with Drawings or Samples

Surface preparation: passivation; polishing; plating; coating; painting; zinc phosphate; dacrotized / dacromet technology

die casting;sand casting process;green sand process;sand casting aluminum;sand cast aluminum;aluminum sand castings;gravity die casting;gravity casting;gravity die casting process;gravity casting process;aluminum gravity die casting;gravity castings;gravity die cast;green sand casting;green sand casting process;green casting sand;foundry sand;sand foundry;foundry casting sand;sand casting foundries;sand molds;molding sand;sand molding;green sand molding;molding sand for sale;aluminium casting;aluminium die casting;die cast aluminium;casting aluminium;die casting aluminium;casting process;aluminium casting process;casting processes;metal casting processes;centrifugal casting process;casting foundry

| Description: | OEM Mental Mold Lost Wax Casting Part with Metal Foundry |

| Main equipments | 6 CNC machining centers, 22 CNC turnings,1Robot welding 1 broacher, 3 resin moldings, HB tester, HRC tester, Roughness tester, Thickness tester, Projector, etc |

| Material capability | 1.Carbon steel, alloy steel, stainless steel 2.Aluminum alloy, brass, bronze 3.Grey iron, ductile iron 4.Plastic: abs, pp, pa, etc |

| Main processes | Machining, Forging, Casting, Welding, Bending, Stamping, Injection |

| Surface treatment | Zinc plate, chrome plate, polishing, paint, powder coat, shot blast, sand blast, phosphating, grinding |

| Main advantages | 1.Manufacturer with established supply partners 2.One-stop service to make your sourcing easy 3.Powerful technical capability 4.Professional and reasonable pricing 5.100%quality guarantee: incoming inspection, 100% key dimension check, tour check, spot check, appearance inspection at packing 6.Very easy to deal with and aim to establish long-term and growing business |

| Service | OEM, ODM, Assembly, etc |

| Shipping term | FOB, CIF, CFR |

| Lead time | In-time, photos for actual status |

| Payment term | Normally, 30%deposit 70% when parts are ready; Negotiable |

OEM Mental Mold Lost Wax Casting Part with Metal Foundry

Q: Why choose Shengao product?

A: We shengao have our own plant-- Weifang Shengao machinery Co.,Ltd, therefore, we can surely promise the quality of every product and provide you comparable price.

Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

Q: Do you provide customized casting products?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there's anything I can help, please feel free to contact with me.