Professional Aluminum Die Casting Service, Die Casting ADC12 Aluminum Spare Part, Custom Aluminum Part Die Casting OEM Factory

SpecificationsAluminum die casting E-bike wheel Hub

1.Direct mold manufacturer

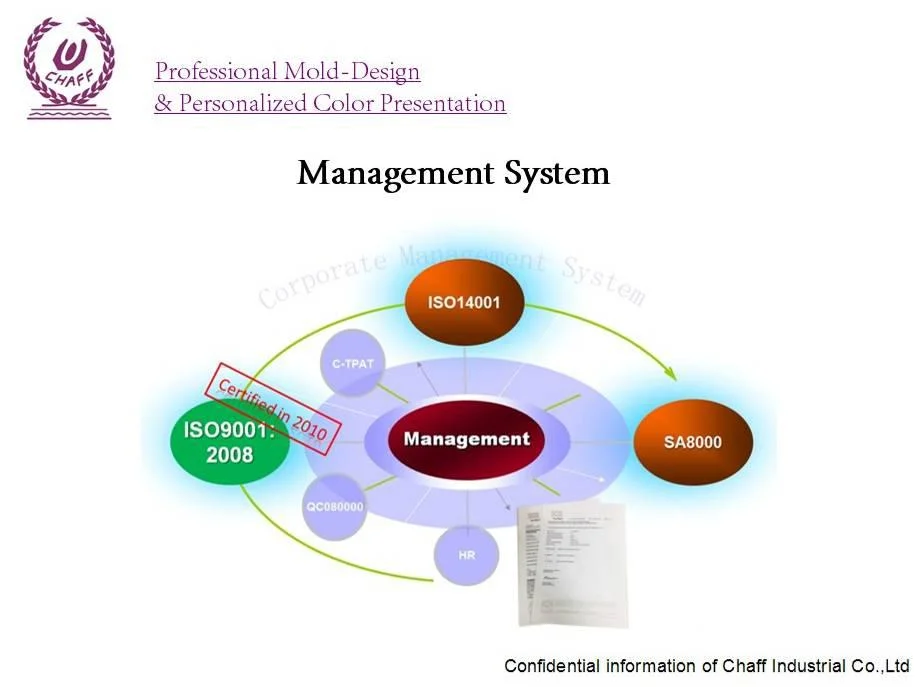

2.OEM service, ISO9001:2008

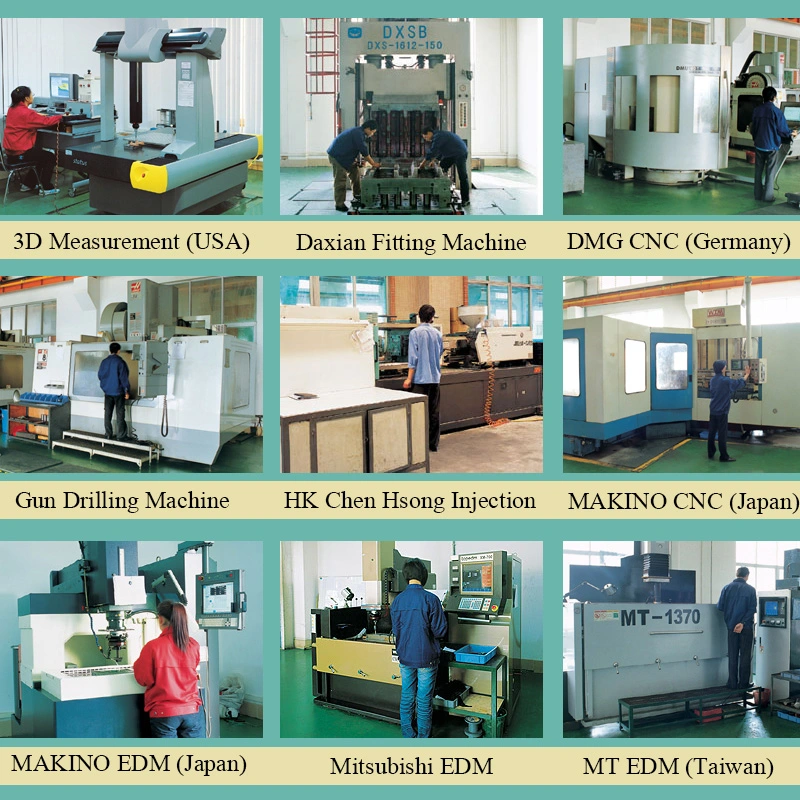

3.CNC Precision Machined

Aluminum die casting motorcycle wheel Hub

1) Material: Aluminum alloy ADC12

2) Product weight from 0.05kg to 15kg

3) Applied software for specification drawings: PRO/E, Auto CAD, Solid Work; UG, CAD/CAM

4) Precision machining: 180 ton to 650ton diecasting machines, CNC lathes, milling, drilling, planning, grinding machines and test facility

5) Surface finish: Zinc/chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis

6) Detailed products range: Gardening parts, auto parts, pump parts, office furniture parts, lamp chimney and so on

7) Other Materials.: A380, A360, B390, ADC10

We can produce aluminum die casting, sand casting parts, aluminum casting, die casting, casting parts, casting, auto parts and other OEM parts

| Product name | Aluminum Alloy Die Casting Parts |

| Material | Aluminum ADC12, A380, Zinc 3 etc |

| Dimensions | Non-standard |

| Weight | 0.03-30kg |

| Surface Treatment | Sand plasting, powder coating, oil painting, Polishing, Anodizing,Texture, Electric plating etc |

| Product Process | Die Casting, CNC machine, Cutting, Drilling,Deburring,Tapping |

| Application | Appliance, Furniture, Auto, Electric industry etc |

| Lead time | 10-30 days after receiving the deposit |

1. ISO9001:2008 Certification

2. Owned mold, die casting,machining and painting workshops

3. Advanced equipment and excellent R&D Team

4. Highly skilled manufacturing process

5. A broad variety of ODM&OEM product range

6. Strict quality Control System

Manufacture Process

1) Process: Die Casting + Machining

2) Secondary Machining: CNC turning, milling, drilling, grinding, assembly to Packing

3) Surface Finish: Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis

Company Advantages:

Dongguan Sunsky Hardware Plastics Co., Ltd. equipped with strong technique strength and all kinds of machining facilities. We accumulated abundant experience of design and manufacturing in the circle of precision plastic moulds, concerned many kinds of products. (such as automotive lighting and accessories, coffee machines, headsets accessories, home appliances, toys, computer peripheral products)and we enjoy high reputation in the industry of automotive lighting and accessories, coffee machines, headsets accessories molds particularly. Punctuality is our bounden duty, quality is treated as our life, as you arrange the work to us, we will not let you have any worries about it.

"Study, innovation, teamwork implementation"are cultivated as our corporate culture, we adopted ISO9001 management system, implemented 7S rules (Seiri, Seiton, Seiso, seiketsu, Shitsuke, Safety, Save)and ensure products quality and delivery date by our technique solution and by all our joint effort. We perform "customer satisfaction, employee dedication, accord with regulation, comprehensive quality"as our purpose, and seek "no the best, only better"for our service goal. New technology and equipments have been introduced and all our members will try our best to supply high quality and good services to meet all customer's requirement and satisfaction.

Innovation and team work is implemented in all the process. In order to ensure the quality, advanced CAD/CAM/CAE systems and more than 160 sets all kinds of high-precision equipments were adopted and all products information is exchanged and shared within the local network. We also designed detailed operation guides and internal management rules, and insisted on the new machining policy, which emphasize" Engineering control all the process and precision machinery auxiliary". At the same time, a full set operation norms and internal management charter have been established, and these have been executed in all the design, produce, testing and other activities strictly. Analysis and demonstration with software instead of on-site operation, which reduce defective rate and ensure the high quality, accurate delivery date and passionate service to be provide to all the clients.

The main clients we served are from European Union, Americas, Asia, Middle East and Taiwan area, most of our moulds and products have been exported to overseas, which is more than 55%of all our producing value. High-precision machining and standardization in building make us have a stand point in this competitive industry.

OUR SERVICE:

1. 100% manufacturer

Our factory is in Dongguancity,Guangdong province,China with 100 staffs who is with best creditability, reliability at your absolute promise . We have many years production experience and export experience.

2. Best material selection.

All our goods are made of best materials from the best suppliers .

3. Good service

We definitely produce all goods by ourselves .

4. Quality control

Every single piece of product, every production procedure is inspected and controlled before packing the goods into export carton.

We ensure every of product shipped are of good quality.

5. After sales service provided

Besides, after sales service is necessary for more understanding for your needs. We do keep a close concern

FAQ:

Q1:Are you a manufacture or trading company?

A: We are a professional cnc machining manufacturer.We have the right to do the import & export business.

Actually, we have this experience for many years.

Q2:What kind of products do you produce?

A: We specializes in producing a variety of mold, cnc machining, die casting and so on.

Q4:Do you support customized products?

A:Sure, we can produce the customized products per your drawings and other requirements.

Q5:Can we print out own logo?

A:Yes, we can make it according to your request.

Q6:Can you provide samples?

A:For our regular products, we offer free samples. For customized cnc machining, tooling and proofing charges need. All free samples not including its courier charge.

Q7:How to ensure that every process's quality?

A: We implement strict ISO quality control, and have 8 steps checking in production .

We have our in-house QC daily and hire third party for randomly inspection.

Q8:What is the lead time of the product?

A:Generally 15-20 workdays after the deposit.

Q9:How about the trading term and payment term?

A:We can discuss this individually.

We can produce aluminum die casting, sand casting parts, aluminum casting, die casting, casting parts, casting, auto parts and other OEM parts

Company advantage

1. ISO9001:2008 Certification

2. Owned mold, die casting,machining and painting workshops

3. Advanced equipment and excellent R&D Team

4. Highly skilled manufacturing process

5. A broad variety of ODM&OEM product range

6. Strict quality Control System

Manufacture Process

1) Process: Die Casting + Machining

2) Secondary Machining: CNC turning, milling, drilling, grinding, assembly to Packing

3) Surface Finish: Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis